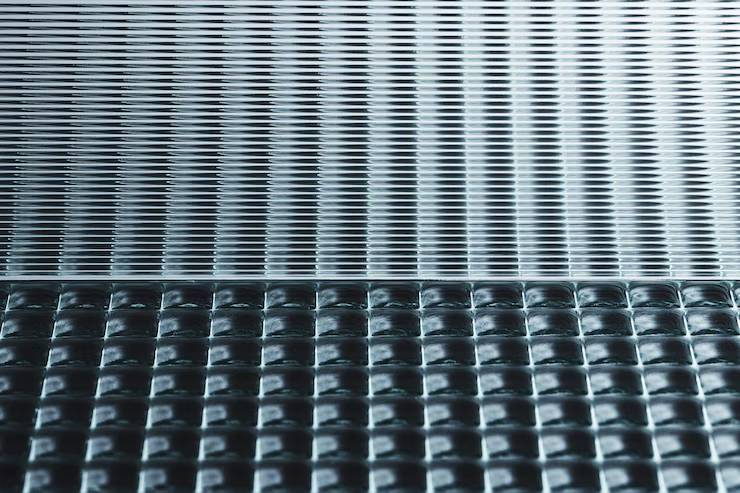

In Plate Heat Exchanger (PHE) systems, gasket selection plays a critical role in ensuring operational integrity, thermal efficiency, and fluid separation. With a wide range of PHE gasket types available, choosing the appropriate material for your application requires careful consideration of fluid compatibility, temperature, pressure, and maintenance protocols.

Understanding Heat Exchanger Gasket Types

Different industries and process requirements demand different heat exchanger gasket types. Common materials include:

- Nitrile Rubber (NBR): Excellent resistance to oils and hydrocarbons; suitable for lower temperature applications.

- EPDM: Ideal for water-based fluids and higher temperature ranges; resistant to alkalis and mild acids.

- Viton (FKM): High-performance gaskets designed for aggressive chemical environments and elevated temperatures.

- Silicone: Frequently used in food, beverage, and pharmaceutical sectors due to non-reactive and hygienic properties.

Each gasket’s material and technical specifications must align with the process fluid and system parameters to ensure optimal performance and safety.

How to Select PHE Gasket Material

Understanding how to select PHE gasket material starts with an evaluation of key process conditions:

- Operating temperature and pressure ranges

- Fluid type (chemical, water, oil, etc.)

- Cleaning requirements (CIP/SIP compatibility)

- Frequency of maintenance or replacement cycles

It’s also essential to consider the compatibility between PHE plates and gaskets, as mismatched materials can lead to premature wear, leakage, and system inefficiencies.

PHE Plate Material Considerations

Selecting the right PHE plate material—such as stainless steel, titanium, or Hastelloy—is equally important. The interaction between plates and gaskets affects overall durability, corrosion resistance, and thermal efficiency, especially in chemically aggressive or high-temperature environments.

Partner with a Reliable Supplier

Choosing a proven PHE gaskets manufacturer or PHE gasket supplier ensures not only access to high-quality materials, but also expert support for selecting the right gasket for your specific process. Customization, technical consultation, and after-sales service are essential for long-term reliability.

Contact SCES today — your trusted PHE gasket supplier — for expert guidance, technical support, and premium-quality PHE plates and gaskets tailored to your application.